Mold FLow Analysis

1. Optimize The Position Of The Gate:

Any injection molding process must include gate location as an essential step. The gates are the critical points at which the molten plastic enters the mold, where it must cool before producing the finished goods.

If the gates are not correctly positioned, the mold portions are not filled with molten plastic. This can be caused by incorrect gate alignment. If the gate were in the wrong place, the distribution of molten plastic would be uneven, resulting in the production of faulty goods.

On the other hand, Moldflow analysis ensures that gate location can be optimized using plastic flow analysis. Consequently, you can determine the proper place for each gate in your mold and ensure that the molten plastic fills the mold evenly.

2. Identify Potential Issues In Components:

Corrections to an incorrectly designed product may be prohibitively expensive. If not identified, it has the potential to cause costly product flaws. The same components must be recreated from scratch multiple times to produce many defective items, increasing production costs. Moldflow analysis can predict where defects will appear in the production of parts before they occur. As a result, you can correct any flaws before the products are manufactured.

3. Prepare For The Fill Patterns:

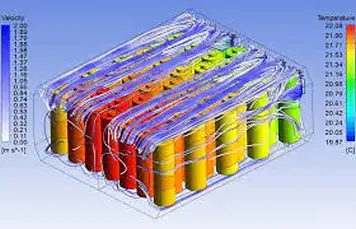

Moldflow analysis can identify and anticipate fill patterns and locate the appropriate gate position. Because of the ability to predict fill patterns, design engineers can simulate the flow of molten plastic into a mold. As a result, it allows them to preview the finished product’s appearance before it is manufactured.

Engineers can use plastic flow analysis to make accurate predictions of fill patterns and redesign more efficient molds.

4. Design Modifications:

Mold flow analysis can help keep errors and mistakes to a minimum during mold design. As a result, it is possible to produce highly high-quality items. As a result, you’ll be able to create a wide range of brand-new designs. Finding new adjustments and solutions is another simple way to facilitate design enhancements for your project.

5. Enhance Overall Product Quality:

The mold flow analysis is a valuable tool for engineers who want to improve the overall quality of their own products. By forecasting the flow of molten plastic, design engineers can make changes to designs to increase output.

The injection molding procedure allows for the production of a large number of high-quality goods. Engineers can thus use moldflow analysis to maintain efficiency and streamline the injection molding process. As a result, there will be fewer opportunities for errors, and the overall quality of the output will improve.

6. Shorter Lead Time:

The term “lead time” refers to the time that elapses between the start of the injection molding process and the point at which the finished product is ready for distribution to customers. Hence, injection molders must opt for a shorter lead time to satisfy customers’ needs and manage the high-volume market distribution of important plastic assembly components.

A variety of factors can influence the lead time. The most common type of flaw occurs during the injection molding process. On the other hand, Moldflow analysis can reduce lead time by allowing for the early detection of potential problems before the start of actual production.

7. Determine The Shrinkage

Companies specializing in injection molding must know the resin shrinkage. This is because the plastic material undergoes temperature changes ranging from high heat to rapid cooling. The majority of items shrink during the cooling process. As a result, you need to have the know-how of mold flow analysis cooling to determine the rate of shrinkage experienced by each material.

Injection molders can determine the rate of shrinkage by using moldflow analysis. Moldflow analysis measures shrinkage rates for all plastic types, including thermoplastics, thermosets, and others. It applies irrespective of the raw material used in plastic production. As a result, manufacturers can use this data to decide the type of resin to use concerning the raw material used and the rate at which their goods shrink.

Extensive analysis capabilities: - Melt Front Time - Air Trap - Weld Line - Sink Mark - Fill Pressure - Temperature - Center Temperature - Bulk Temperature - Moldability (Confidence of Fill) - Velocity Vector - Max. cooling Time - Max. Shear Rate - Max. Shear Stress - Frozen Layer Ratio - Volume Shrinkage - Material Orientation - Gate Contribution - Fiber Orientation